Engineered isoprene production from Chlamydomonas reinhardtii using herbicide selection markers and CO2-fed cultivation optimization through multi-parallel photobioreactor headspace gas analysis

Engineered isoprene production from Chlamydomonas reinhardtii using herbicide selection markers and CO2-fed cultivation optimization through multi-parallel photobioreactor headspace gas analysis

Yahya, R. Z.; Overmans, S.; Wellman, G. B.; Lauersen, K. J.

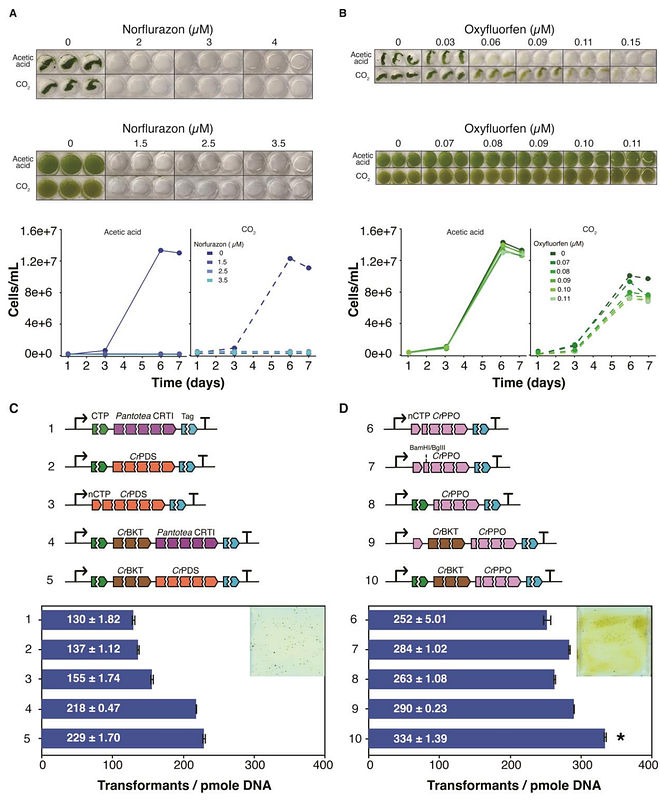

AbstractMetabolic engineering requires selection markers for transformant generation. However, use of antibiotic resistance is of concern for potential horizontal gene transfer in the environment. Herbicide resistance markers are an alternative for photosynthetic cell line engineering as these agents are plant-specific with resistance mechanisms that can be generated from mutations of endogenous genes. Here, we developed norflurazon and oxyfluorfen resistance markers for nuclear genome transformant selection in the model green alga Chlamydomonas reinhardtii. These were used to engineer robust isoprene biosynthesis by facilitating overexpression of a yeast isopentenyl-diphosphate delta-isomerase (ScIDI), the alga\'s own beta carotene ketolase (CrBKT), and the sweet potato isoprene synthase (IbIspS). Further UV-C mutagenesis and colony selection were employed to improve yields to ~350 mg isoprene L-1 culture on organic carbon. It was then possible to optimize CO2-driven cultivation and isoprene biosynthesis in batch and continuous processes using multi-port, real-time, in-line mass spectrometry coupled to parallel photobioreactors. The highest isoprene yields in batch were achieved under 900 E illumination and 33 {degrees}C and, in turbidostat mode, ~51 mg isoprene L culture-1 day-1 was achieved for 3 days concomitant with algal biomass production. Cultivation of the engineered alga directly in effluent from an anaerobic membrane bioreactor was also conducted. Isoprene production was concomitant with removal of ammonium and phosphate from the wastewater, and biomass production was similar to that in replete medium. Isoprene yields exhibited gradual reduction after each successive repetitive refresh, which could be mitigated by supplementation of trace elements. The results demonstrate that engineered algae could be used as a secondary wastewater treatment step while generating both biomass and volatile co-products like isoprene.