Mind the corner: Fillets in cryo-FIB lamella preparation to minimise sample loss caused by stress concentration and lamella breakage

Mind the corner: Fillets in cryo-FIB lamella preparation to minimise sample loss caused by stress concentration and lamella breakage

Gorelick, S.; Velamoor, S.; Cleeve, P.; Trepout, S.; Ying, L.; Naranbhai, V.; Ramm, G.

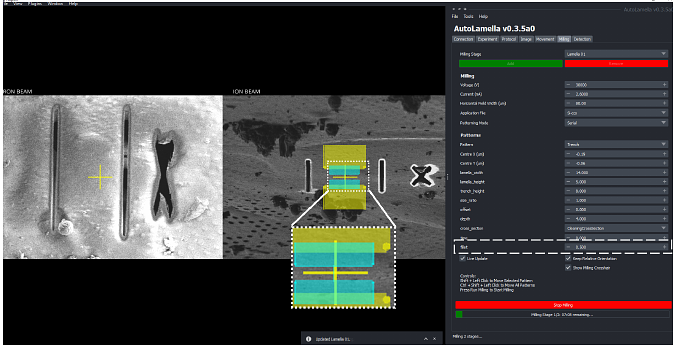

AbstractCryo-FIB milling of biological specimens is a critical and limiting step in the cryo-electron tomography workflow. Preparing electron-transparent cryo-lamellae is a serial, low-throughput process. Even with automation, a skilled operator can typically only produce 15--25 lamellae in a single cryo-FIB session. During sample handling, milling and transfer, the cryo-fixed cells as well as the supporting film layer face various mechanical forces and thermal stresses due to temperature fluctuations. Moreover, after cells are cryo-FIB milled, the resulting thin lamellae continue to endure external forces from mechanical handling and thermal stress. We propose a simple, yet highly effective modification to the standard rectangular milling pattern by implementing \"fillets\" or corner smoothing providing better mechanical stability. This adjustment helps to avoid sharp corners at the lamella edges, thereby reducing stress concentration. As a result, this modification decreases the likelihood of lamella breakage and improves the overall yield of ready-for-TEM lamellae by 33% as verified experimentally.